PTFE envelope and enveloped gaskets!

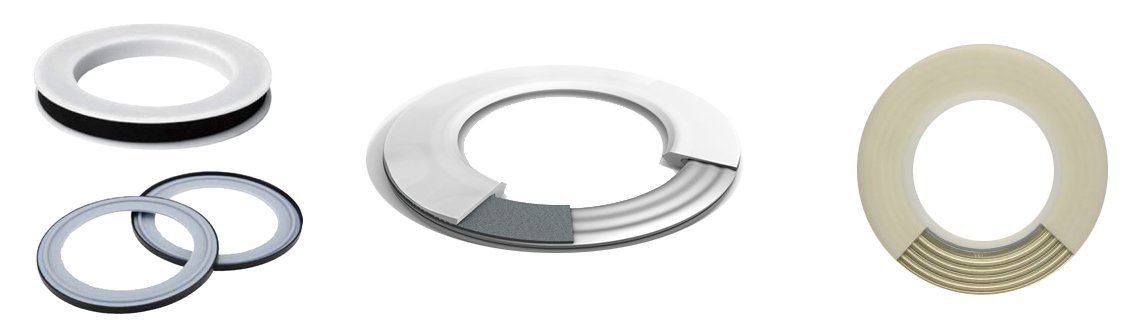

Our company produces all types of envelope seals with different fillers (rubber, paronite, and more.)

We use only 100% pure PTFE for the production of envelopes, which provide excellent stability and excellent mechanical seal between the flanges, pipes, tanks and reactors.

PTFE protective envelope can be made oval, round or by a customer drawing. The thickness of the filler material may be from 1.0 to 25,0mm. The filler can be any existing material.

PTFE envelope can be set on a ready seal from the inside. Thus, it would supply the product in contact only with PTFE layer, filler can be any other material (rubber, silicone tube, Paranit). This solution, allows the customer to save money, and most important, pushes the boundaries of the technical characteristics of the gasket.

Example: If the client is working with Aggressive chemistry, and to connect the pipeline used enameled flanges, while the ability to install the PTFE seals of sheet material is missing. For proper sealing, requiring high torque on a bolts, which can lead to damage the flange surface.

Solution: Using a soft filler material (rubber or paronite) and PTFE protective envelope seal can get a softer compression without losing inert PTFE properties.

This principle are well-proven and widely used in chemical, petrochemical, pharmaceutical and engineering industries.

Physical and mechanical characteristics:

Excellent resistance to acids, protects the insert

May come into contact with foodstuffs

Do not leave any marks on the flange surface, which allows to replace quickly

Resistance to sudden temperature changes

Excellent dielectric properties

Low level of porosity

For more information about the product you can get from our managers by phones specified in section How to find us.