Quick release coupling - element of hose connections, hoses, various parts of the industrial equipment, which allows to make a fast connection elements. They can be made from different materials (aluminum, stainless steel, brass, titanium, bronze, various metal alloys, various plastic compositions).

All market quick release coupling (QRC) are divided into 2 parts:

80% - is the QRC made according to ISO standard. In this case the manufacturer is not important, all QRC interchangeable: for example, part of the "female" can be from the producer in Europe, as part of the "male" - from Asia. ISO QRC advantage is cheapness, availability of the warehouses of many vendors including our company.

20% - quick couplings, sold under its own brand products, which have a unique design that allows use of couplings and nipples QRC only this manufacturer. Advantages: As a rule, high reliability products, the possibility of claims in case of breakage. Disadvantage: no similar compounds from other manufacturers, only alternative solutions.

Materials used

On the duration of the operation of the QRC is greatly affected by the materials used. The most important factors in selecting compounds are, true test range of body material and the corresponding seals. Check the suitability of a particular material it is in your case, you can see in our Technical Information

Quick Release Couplings made of many kinds of metal such as steel, copper, aluminum, stainless steel, as well as various polymer materials: polyimide, polypropylene, PVDF, PTFE, etc., having characteristics corresponding to the specific application..

To make the anti-corrosion properties of such methods of treatment like galvanizing, polishing, plating, chrome plating, chemical deposition of nickel plating, anodising and application of hard coatings.

Types and sealing materials

The QRC standard is used annular elastomeric seals. Elastomers at a temperature below the decomposition temperature, are polymeric materials reticulated (cured) at a temperature which is less than -50 ° C as glass become solid and thick liquid exhibit properties at high temperature (100-250 ° C) to the decomposition temperature. Thus at temperatures below the decomposition temperature, in particular at room temperature, they exhibit rubber elasticity. The main raw material for the production of elastomers is rubber. Characteristics of elastomers:

low permeability to gaseous substances;

resistance to aging and wear and tear;

elasticity at low temperatures;

elasticity;

ensuring constant pressure;

resistance to high temperatures and swelling.

Elastomers possess chemical resistance to substances such as oil, fuel, dilute acids and bases, saline solutions, water of different qualities, gases and solvents.

Very often applied nitrile-butadiene rubber (NBR), which allows to modify the properties of the final material in a wide range by using different components acrylonitrile (acrylonitrile content).

It is also often used fluoroelastomers-FKM (FPM) or Viton. To date, developed many types of materials, which allow to obtain the properties required in the particular application. If the above gaskets do not have adequate resistance to the effects of any substances, are often used materials based on ethylene-propylene-diene monomer - EPDM. Through careful application of the elastomer substrate characteristics, the area of possible application of the QRC is expanding significantly. Particular attention is drawn perfluoro. Their resistance to chemicals is almost equal to the corresponding index of PTFE (PTFE), but provided the elastic properties typical of elastomers.

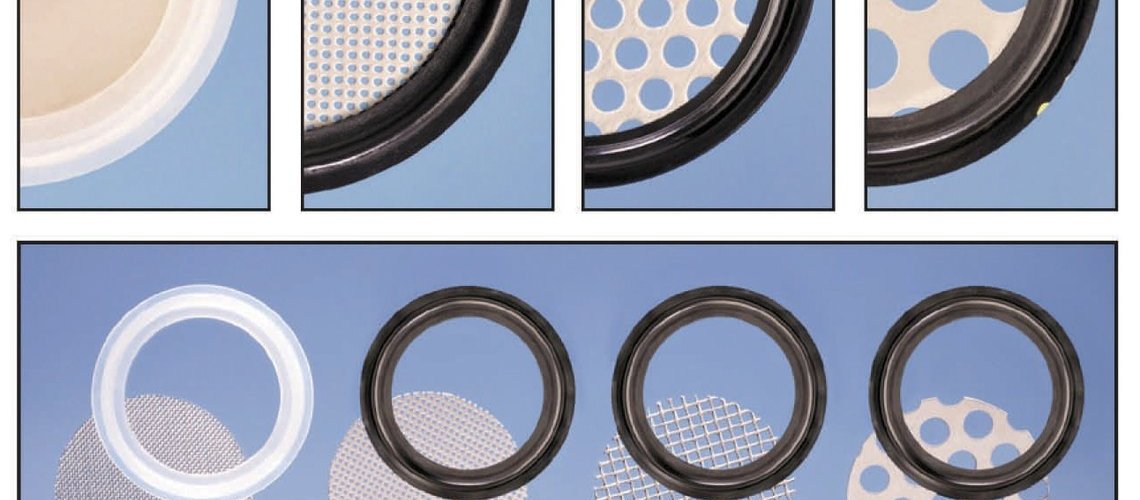

We are ready to organize the delivery to your company all the most popular types of seals for all kinds of QRC. These seals may be formed of the same material or combinations of materials. Our stock is always available for sealing joints of the following types: Camlock, GK, Tank Wagon, DIN, SMS, Cardan, PERROT, BAUER, STORZ, and many others.

Also in the proposal are sealed with the presence of filtration elements (mesh), the product of the PTFE envelope of performance, etc.

For more information obraschaёtes our managers.