Teflon, the working layer!

Teflon - a unique synthetic material. According to the chemical resistance of PTFE is superior to the noble metals, enamels and special steels. The most aggressive chemicals (acids, bases, oxidizers, solvents) do not exert any influence on it even at a high temperature. On impact PTFE melts only alkali metals, their solutions in ammonia, chlorine trifluoride and elemental chlorine at high temperatures. Teflon is operated at temperatures from - 269S 260S +, the upper limit is not limited to the loss of chemical resistance, and a decrease in physical and mechanical properties. When heated above + 327 C melts, but does not go into the polymer viscous fluid state to the decomposition temperature of 415 C.

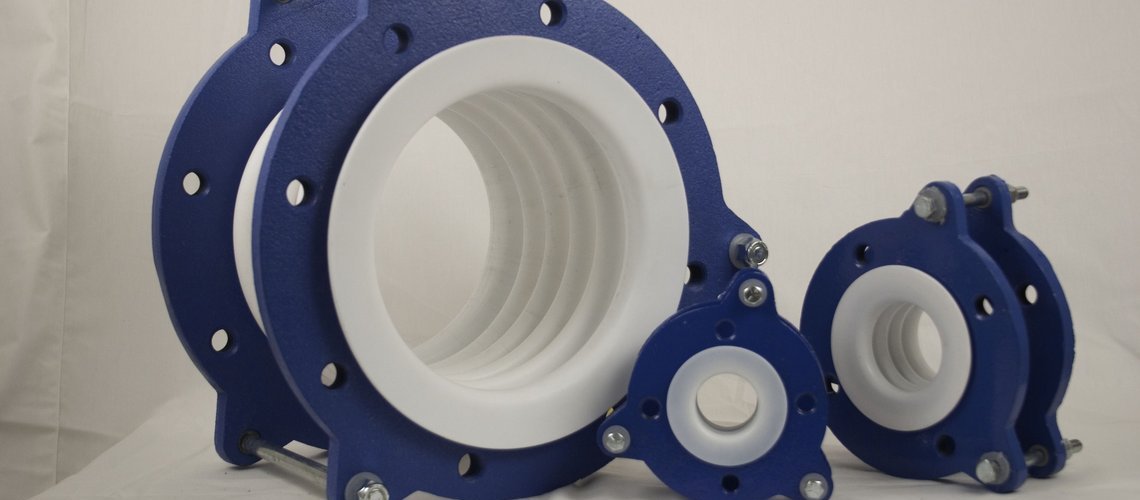

There are three basic types of expansion joints, metal (steel), rubber and textile. Recently, new materials processing technology will produce joints of pure PTFE. This design has a relatively high cost and often irreplaceable classic products, where the inner layer is made of Teflon. By combining several types of products in one can obtain the desired parameters, without compromising the quality and maintaining a competitive price.

Expansion joints are designed to compensate for thermal expansion and pipe vibration. For transporting liquid corrosive media (highly concentrated acid and alkali) at high pressure, at high temperatures, the internal layer is made of PTFE. As PTFE is suitable when working with food, it is confirmed by appropriate certificates.

Our company is able to calculate and organize the delivery of such products to you as soon as possible. In our offer you can find all types of products without exception. Depending on your needs, we'll show you the right solution and provide competitive price offer!

For more information, please contact our specialists.