Polyetheretherkethone KETRON PEEK

Polyetheretherkethone KETRON PEEK

The semi-crystalline thermoplastic material.

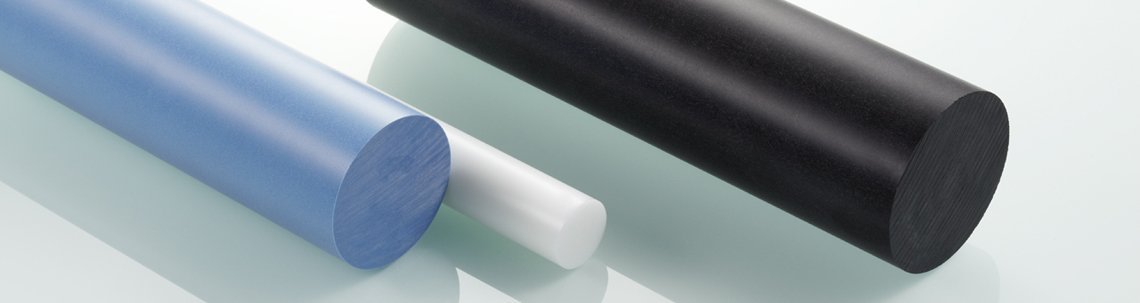

Polyoxymethylene (POM), also known as acetal, polyacetal and Polyformaldehyde is a structural thermoplastic material used for the manufacture of precision parts that require high strength, low friction and permanence of part dimensions. Polyacetal is characterized by high strength, hardness and stiffness when exposed to temperatures of up to -40 ° C. In most cases, due to a highly crystalline structure, the polyacetal has a matte white, but may be made of any color.

Polyacetal homopolymer is a semicrystalline polymer with a melting point of 175 ° C, while the copolymer has a somewhat lower melting point of about 162-173 ° C.

Polyacetal is a durable material with a very low coefficient of friction. Because it is easily oxidized, then thereto are added antioxidant additive. The two most common methods are injection molding and extrusion molding. How, from polyacetal molding to produce parts that need to have high performance characteristics. Polyacetal is widely used in the automotive industry and consumer electronics.

Used in heavy conveyor systems at low temperatures.